Process Of Fluid Catalytic Cracking Information

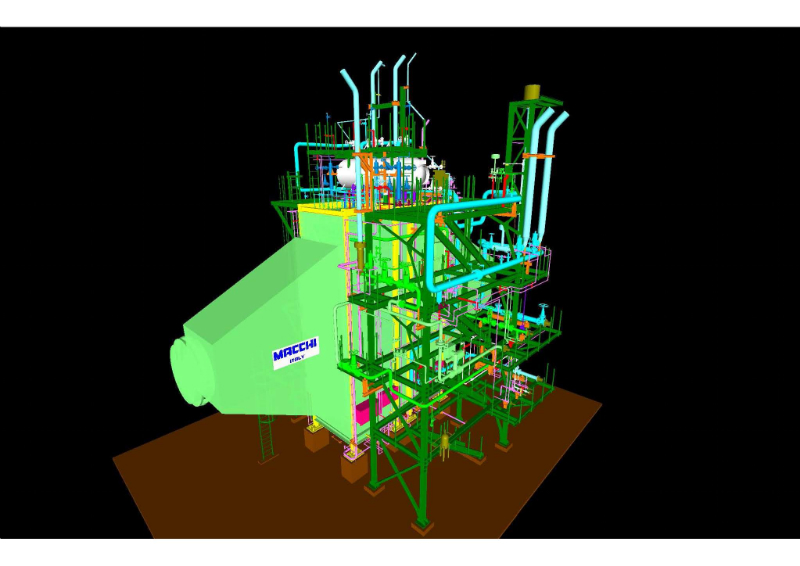

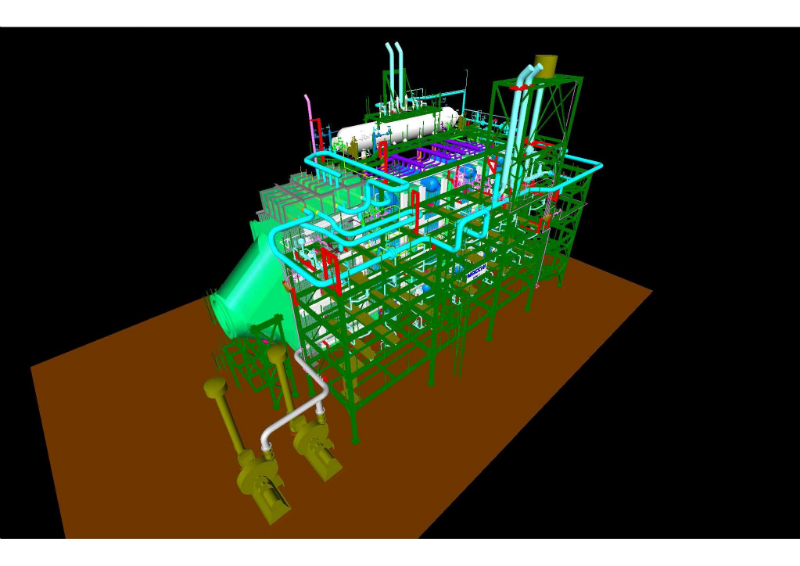

In this process the gas oil is preheated in the drums or storage and pumped to the riser or reactor-generator. The riser provides contact between the gas oil and the catalyst, which are atomized into the stripper.

UOP-0009-S: UOP: Fundamentals - Fluid Catalytic Cracking (FCC) Standard Process Implementation - Seminar. Fluid Catalytic Cracking FCC Definition - Fluid catalytic cracking (FCC) is a refining process of gas oil, which could not be distilled in an atmospheric.

The steam present in the stripper along with controlled temperatures and pressures help to separate the spent catalyst from the vaporized or liquid hydrocarbons. The levels of the spent catalysts are maintained in the stripper and also the regenerator. The regenerator purifies the catalyst and channels it back to the riser to maintain the required amount in the fluid catalytic cracking unit.

The hydrocarbon vapors flow into the fractionator or main column, which condenses them into trays. The main column de-superheats the vapor and at the same time cools it as it washes away the catalyst present inside. Further distillation and refining cycles are applied to ensure that gasoline and diesel are produced. Fluid catalytic cracking is a fundamental complex process in the petroleum industry, as it converts high-boiling and low-value gas oil into valuable transportable oils. Pipelines are mostly affected by gas oil or sand oil which is present in crude oil. Internal corrosion in the pipeline is caused by the presence of water and sediments.

The lighter oil from fluid catalytic cracking does not allow water or sediments to settle and accumulate on the surface of the pipe floor; reduced amounts of water from this process have significantly helped in preventing corrosion.

Courses Related to the UOP: Fundamentals - Fluid Catalytic Cracking (FCC) Standard Process Implementation - Seminar Course. Course participants will learn the fundamentals of refining process design. The course is aimed at refinery or petrochemical plant technical staff. Detailed Course Information:.

KMSpico 9.2.3 Final Windows 7 Activator Free Download that's free. It Activate windows 7 all versions With no serial/Keygen/Crack/ or Patch. KMSpico 9.2.3 Final Windows 7 Latest Activator Full Version: KMSpico 9.2.3 Final Windows 7 Latest Activator Full Version is Here. It is a very simple and u. Kmspico 9.2.3 torrent. KMSpico 9.2.3 Final Download Latest for Activation of Windows 8 Home Basic Professional, Home Premium Ultimate Enterprise Office 2007 2010 KMSPICO 9.2.3. I have KMSPico 9.1.3 already installed on PC everything is working fine, do I need to update to KMSPico 9.2.3? Windows 10 Activator – KMSPico 10.2.1. KMSpico is one of the best activator for windows and office. You can use this KMSpico to activate windows 7, windows 8, windows 8.1, office 2010 and also office 2013.

Course participants will gain practical insights into the principles of process design. Detailed Course Information:. Course participants will learn how to effectively manage energy consumption within the refinery, as well as how to enhance the profitability of existing projects across the site through energy integration. Detailed Course Information:.

Course participants will gain an understanding of the HF Alkylation Process and operation of the unit. Detailed Course Information:.

Course participants will learn the fundamentals of UOP Butamer Process. Detailed Course Information:. Course participants will learn the fundamentals of the UOP Penex Process, including unit startup, shutdown and emergency operations. Detailed Course Information:. Course participants will get in-depth understanding of the UOP Unicracking Process, which includes both theory and practical applications.

Detailed Course Information:. Course participants will learn the principles of catalyst regeneration and the regeneration tower operation, including how to optimize catalyst performance and maximize catalyst life.

Detailed Course Information:. Course participants will learn in-depth about process variables, controlling the heat balance, catalyst functionality and management, process optimization, fluidization, and troubleshooting. Detailed Course Information:.

Dynamic Modeling Of Fluid Catalytic Cracking Unit

Course participants will gain an in-depth understanding of the CCR Platforming unit. Detailed Course Information:. Course participants will learn the operation, maintenance and troubleshooting of the UOP Fixed-Bed Platforming unit, with emphasis on optimizing catalyst performance and maximizing catalyst cycle life. Detailed Course Information.